Before diving deep into the world of AI-powered transformation, it’s important to understand why AI in industrial automation matters now. The manufacturing and industrial sectors are undergoing a massive shift toward intelligent operations, where machines not only perform tasks but also think, learn, and optimize. This change is not just about technology; it’s about staying competitive in a rapidly evolving global market.

Why AI in Industrial Automation Matters Now

Artificial Intelligence has become a key driver of change in modern industries. AI in industrial automation helps machines and systems make smart decisions based on data rather than fixed rules. This shift allows factories to work faster, use resources better, and improve product quality.

In traditional automation, machines could follow instructions but could not adapt to changes. With AI, automation becomes intelligent. Machines can learn from data, detect patterns, and predict outcomes. For example, AI systems can identify equipment issues before breakdowns happen, reducing costly downtime. They can also inspect products for defects more accurately than human workers.

Industries such as automotive, electronics, and pharmaceuticals are using AI-powered automation solutions to improve efficiency and safety. It is helping companies save energy, reduce waste, and meet higher production demands without adding more manual labor. For many businesses, adopting AI in industrial automation is now a way to stay competitive, not just a technological upgrade.

Global manufacturing is moving toward smart factories where machines communicate, analyze, and optimize processes in real time. This helps businesses achieve better consistency, lower costs, and faster delivery. As more companies invest in intelligent systems, AI in industrial automation is becoming an essential part of Industry 4.0, shaping the future of production.

In simple terms, AI makes automation smarter. It allows industries to move from reactive operations to proactive ones. Companies that start early with AI integration will have stronger control over quality, performance, and innovation in the years ahead.

AI in Industrial Automation Market Summary

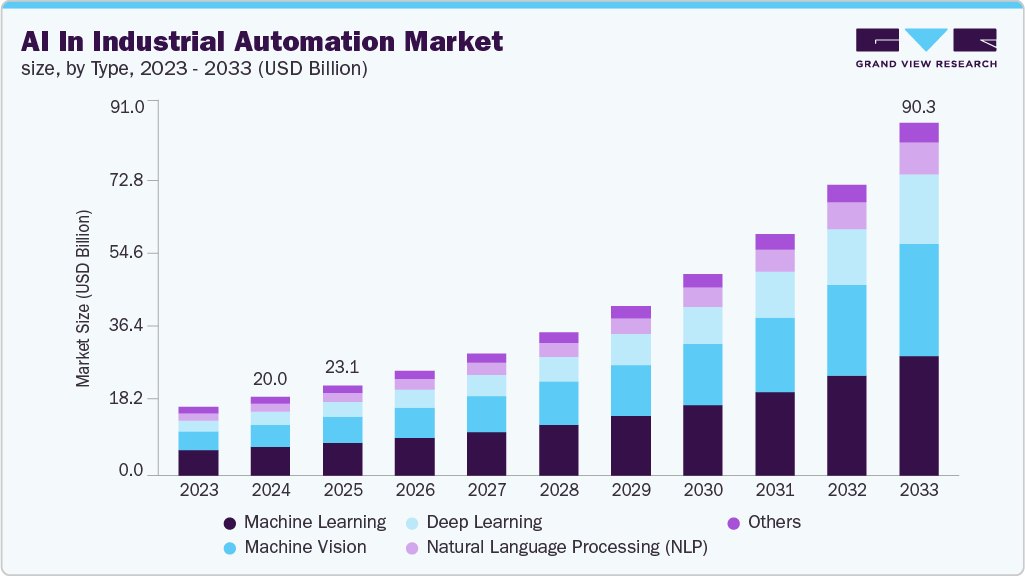

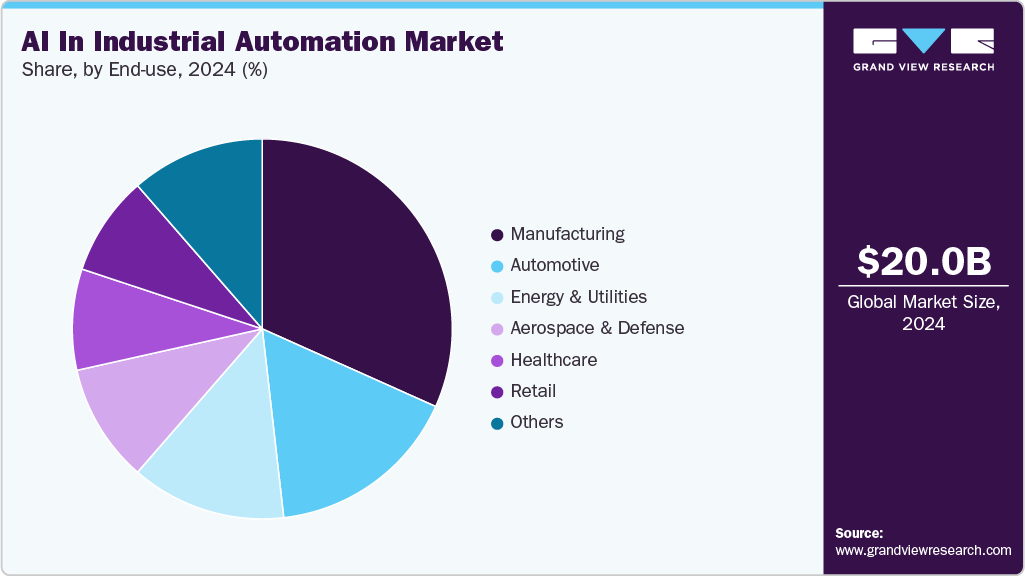

According to a recent Grand View Research report, the global AI in industrial automation market was valued at USD 20.02 billion in 2024 and is projected to reach USD 90.28 billion by 2033, growing at a CAGR of 18.6% from 2025 to 2033.

This rapid growth is driven by the increasing adoption of predictive maintenance, AI-enabled robotics, machine vision systems, and digital twin technologies that enhance production efficiency and resource management.

In 2024, North America held the largest market share of over 36%, led by strong adoption across the United States. Asia Pacific is expected to grow the fastest through 2033, fueled by rising investments in smart factories across China, Japan, and India. The machine learning segment accounted for more than 36% of the market, mainly due to its use in predictive maintenance and process optimization. The predictive maintenance and machinery inspection segment led by application, capturing about 28% of global revenue.

By end use, the energy and utilities sector is set to grow at the fastest rate, exceeding a 23% CAGR, as industries focus on grid reliability and energy efficiency. Key players such as Siemens AG, ABB Ltd., General Electric, Mitsubishi Electric, and Schneider Electric are driving innovation with AI-based robotics, digital twins, and analytics platforms.

Overall, the AI in industrial automation industry is evolving rapidly as manufacturers seek smarter, more adaptive production systems. With AI-driven insights improving decision-making, quality, and productivity, the global industrial landscape is moving toward an intelligent, data-centric future.

Why Businesses Are Adopting AI in Industrial Automation

A. Predictive Maintenance to Prevent Downtime

Companies are adopting AI-driven predictive maintenance to detect equipment issues before failure occurs. This approach reduces unplanned downtime, extends machine life, and lowers maintenance costs by relying on real-time analytics and sensor data.

B. Improved Quality Control with Machine Vision

AI-powered machine vision systems identify defects and irregularities faster and more accurately than manual inspection. This enhances product consistency, reduces waste, and ensures compliance with strict quality standards.

C. Enhanced Efficiency Through Robotics

AI-integrated robotics automate repetitive tasks, improving speed, precision, and scalability. These robots can adapt to production changes, optimize workflows, and handle complex assembly processes with minimal human intervention.

D. Optimized Resource Management with Digital Twins

Digital twin technology creates a virtual model of machines and processes, allowing operators to simulate, monitor, and optimize performance. This reduces energy use, improves resource allocation, and increases operational agility.

E. Cost Reduction and Process Optimization

AI enables real-time process monitoring and decision-making, helping industries cut operational costs. By analyzing data from production lines, AI suggests the best ways to increase throughput and reduce energy consumption.

F. Increased Workplace Safety

Automated systems supported by AI help minimize human exposure to hazardous environments. Predictive analytics identify potential safety risks early, ensuring safer and more reliable operations.

G. Competitive Advantage and Scalability

Businesses investing in AI automation gain the flexibility to scale production faster and adapt to demand changes. The ability to make data-backed decisions helps maintain competitiveness in rapidly evolving industries.

The growing adoption of AI in industrial automation is not just about efficiency but transformation. After understanding why industries are rapidly moving toward intelligent automation, it’s important to see how these systems actually function behind the scenes.

Find details on our Software Consulting Services for adopting AI in your business. Also, check out our AI software development services page.

How AI in Industrial Automation Works

AI in industrial automation works through a series of connected stages that transform raw machine data into intelligent actions. It begins with the collection of real-time data from sensors, industrial equipment, and IoT devices placed across production lines. These sensors continuously monitor parameters such as temperature, vibration, and energy consumption. The gathered information is then sent to centralized or cloud-based systems, where AI algorithms process and organize it for further analysis.

Machine learning models study this data to identify patterns, detect irregularities, and predict potential failures before they occur. Alongside this, computer vision systems powered by AI play a key role in quality inspection, using cameras and image recognition to detect defects and maintain precision in production. Once the analysis is complete, predictive analytics forecast maintenance requirements, while prescriptive analytics recommend actions to optimize performance. These AI-driven insights enable automated systems and robots to make autonomous decisions, such as adjusting operations or balancing energy loads without human intervention.

Over time, the system continues to learn from new data, improving accuracy, efficiency, and reliability. Through this continuous feedback loop, AI in industrial automation not only streamlines processes but also creates a self-improving ecosystem that supports smarter, safer, and more efficient manufacturing operations.

With a clear understanding of how AI functions within automated industrial systems, it becomes easier to see its real-world impact. From manufacturing floors to energy grids, AI is reshaping how industries operate, ensuring higher precision, reduced costs, and continuous improvement.

Popular Applications and Benefits of AI in Industrial Automation

1. Predictive Maintenance

What it does:

Predictive maintenance uses AI and sensor data to monitor machine health and predict equipment failures before they occur. It helps companies schedule maintenance only when needed, minimizing downtime.

Features:

- Real-time monitoring using IoT sensors and AI analytics.

- Early detection of anomalies such as vibration or temperature shifts.

- Automated alerts for timely maintenance scheduling.

Benefits:

- Prevents costly breakdowns and reduces downtime.

- Increases machine lifespan and operational efficiency.

- Optimizes maintenance resources and planning.

2. Machine Vision and Quality Inspection

What it does:

AI-based machine vision systems inspect products during production, identifying defects or inconsistencies instantly. This ensures uniform quality and eliminates manual inspection errors.

Features:

- High-speed image capture and defect detection using AI models.

- Real-time quality analysis and feedback.

- Integration with production lines for automated adjustments.

Benefits:

- Guarantees consistent product quality.

- Cuts inspection time and minimizes human error.

- Improves customer satisfaction and compliance standards.

3. AI-Powered Robotics and Process Automation

What it does:

AI-enabled robots automate repetitive or complex industrial tasks. They can learn, adapt, and collaborate safely with humans on the production floor, improving overall productivity.

Features:

- Adaptive robotics powered by AI and machine learning.

- Real-time data-driven task execution and optimization.

- Safe human-robot collaboration (cobots).

Benefits:

- Accelerates production with high accuracy.

- Reduces human involvement in risky or repetitive tasks.

- Increases scalability and operational flexibility.

4. Digital Twin Technology

What it does:

Digital twin technology creates a virtual model of a physical machine or system. This twin mirrors real-time conditions, allowing industries to simulate, test, and optimize performance without disrupting operations.

Features:

- Real-time data synchronization with physical assets.

- AI-based simulations and scenario testing.

- Integration with IoT platforms for continuous updates.

Benefits:

- Enhances decision-making with predictive insights.

- Reduces waste by testing virtually before implementation.

- Improves system reliability and process optimization.

5. Supply Chain and Energy Optimization

What it does:

AI analyzes logistics, production data, and energy consumption to optimize supply chain operations and resource usage. It ensures better forecasting, load balancing, and sustainability.

Features:

- Demand forecasting and dynamic scheduling using AI models.

- Energy load monitoring and automated optimization.

- Integration with ERP and industrial control systems.

Benefits:

- Cuts energy and operational costs.

- Improves production planning and inventory management.

- Supports sustainability and carbon reduction goals.

AI in industrial automation can make businesses smarter, faster, and better by turning data into actionable intelligence, enabling real-time decisions that improve efficiency and accuracy.

Smart automation systems powered by AI continuously learn from production data, helping industries predict issues before they occur, minimize downtime, and optimize energy and resource use. These systems allow factories to operate faster by streamlining workflows, automating repetitive tasks, and coordinating robotics with precision.

They also make operations better by enhancing product quality, ensuring safety compliance, and enabling scalability without increasing costs. In essence, AI empowers industries to move beyond traditional automation toward adaptive, intelligent operations that grow stronger and more efficient with every process cycle.

As industries increasingly adopt AI to automate processes and improve productivity, building an AI-driven automation system requires a structured development process. Understanding this process and knowing how to choose the right technology partner are key steps toward successful implementation.

Further, read an article to learn how IT consulting and services can enhance efficiency, strengthen security, and drive growth.

Development Process for AI in Industrial Automation

Building AI-driven industrial automation systems involves a structured approach that ensures accuracy, scalability, and seamless integration. Here’s how the development process typically unfolds:

Step 1. Requirement Analysis – Define specific industrial goals such as predictive maintenance, quality inspection, or production optimization. Identify the processes that can benefit most from automation.

Step 2. Data Collection and Preparation – Gather historical and real-time data from sensors, IoT devices, machines, and production lines. This data is cleaned, labeled, and structured for AI model training.

Step 3. Model Development – Choose the right AI algorithms such as computer vision, deep learning, or reinforcement learning. Develop and train models that can recognize patterns, predict anomalies, or optimize processes.

Step 4. Integration with Control Systems – The AI models are integrated with existing automation systems like PLCs, SCADA, or MES to ensure real-time decision-making and control.

Step 5. Testing and Validation – The system undergoes rigorous testing in both simulated and live environments to ensure performance, reliability, and safety.

Step 6. Deployment and Monitoring – After validation, the AI solution is deployed on-site or in the cloud. Continuous monitoring helps fine-tune performance and adapt to changing industrial conditions.

Step 7. Maintenance and Continuous Improvement – Regular updates and retraining of AI models keep the system aligned with evolving operations and new data patterns.

How to Choose the Right AI Industrial Automation Company

Selecting the right partner for AI in industrial automation can determine the success of your digital transformation. Look for a company with proven expertise in AI, IoT, and automation technologies. Evaluate their experience across industries such as manufacturing, logistics, or energy. Ensure they provide end-to-end support, from strategy and development to integration and post-deployment maintenance. Transparency in cost, flexible engagement models, and adherence to safety and compliance standards are also crucial.

A trusted AI automation partner will not only deliver a working solution but also help you future-proof your operations with scalable, intelligent automation systems.

We have a framework ready for you.

Click to explore how our modular, enterprise-ready AI framework accelerates digital transformation with intelligent, adaptive technologies, delivering MVP or PoC in just 4 weeks.

As industries move from concept to execution, one key question often arises: how much does it cost to implement AI in industrial automation? Understanding the pricing structure helps businesses plan strategically and invest wisely in their automation journey.

Cost and Pricing for AI in Industrial Automation

The cost of developing and implementing AI in industrial automation depends on several factors, such as project complexity, data requirements, and system integration. Here’s a breakdown of the major cost components:

- Scope and Complexity – Simple automation projects like quality checks or sensor-based alerts cost less than advanced predictive systems or robotic control powered by deep learning.

- Data Requirements – High-quality, large-scale data collection and labeling significantly impact the budget. Industries with existing sensor infrastructure generally spend less on data preparation.

- Technology Stack – Costs vary based on whether the solution uses cloud-based AI services or on-premises setups. Cloud AI services often reduce upfront investment but include recurring costs.

- Integration Needs – Connecting AI systems with legacy automation tools, ERP, or manufacturing execution systems adds customization and integration costs.

- Deployment and Maintenance – Ongoing costs include model retraining, monitoring, software updates, and cybersecurity management to maintain reliable and secure operations.

On average, small to mid-sized AI automation projects may range from $50,000 to $250,000, while large-scale enterprise implementations can exceed $500,000, depending on customization and scope.

Investing in AI-powered automation delivers long-term ROI by reducing downtime, optimizing resource use, enabling predictive maintenance, and improving production efficiency.

Future of AI in Industrial Automation

The future of AI in industrial automation promises smarter operations, seamless human-machine collaboration, and sustainable growth. As industries transition toward Industry 5.0, AI will drive innovation by enabling machines to learn, adapt, and optimize processes autonomously.

a. Hyper-Automated Factories

Factories of the future will operate as intelligent ecosystems. By combining AI, IoT, robotics, and digital twins, production lines will continuously adjust to real-time data. This means optimized resource use, reduced downtime, and consistent quality without human intervention.

b. Human-AI Collaboration

AI will empower, not replace, the workforce. Intelligent systems will take over repetitive tasks and assist humans with data-driven insights, improving safety and decision-making accuracy. Workers will focus more on strategy and creative problem-solving.

c. Edge and Cloud Integration

Next-generation AI automation will blend edge computing for instant local decision-making and cloud AI for large-scale data analysis. This hybrid approach will ensure faster responses, minimal latency, and centralized optimization.

d. Sustainability and Efficiency

AI will enable energy-efficient and environmentally responsible manufacturing. By analyzing consumption patterns and optimizing resource allocation, industries can reduce waste, carbon emissions, and operational costs simultaneously.

e. Predictive and Prescriptive Analytics

AI-driven analytics will move beyond predicting issues to prescribing real-time corrective actions. This evolution will enable autonomous maintenance, extending equipment life and ensuring near-zero downtime.

f. Security-First Automation

As connectivity grows, so does the need for protection. AI will play a central role in industrial cybersecurity by identifying threats, preventing data breaches, and maintaining system integrity without disrupting operations.

The future of AI in industrial automation is about resilience, intelligence, and adaptability. Businesses that embrace these technologies today will lead the next wave of industrial transformation tomorrow.

Conclusion

AI in industrial automation is reshaping how industries operate, optimize, and grow. From predictive analytics to autonomous machines, the integration of AI is making manufacturing smarter, faster, and more efficient. As we move toward Industry 5.0, the collaboration between humans and AI will become even more important, helping businesses achieve greater productivity, sustainability, and safety.

To stay competitive, companies must embrace AI-driven innovation today rather than wait for the technology to become mainstream. The shift toward intelligent automation is not just about efficiency; it’s about building a resilient, adaptive, and data-driven industrial ecosystem.

If you are ready to transform your operations with intelligent automation, Emorphis Technologies can be your trusted partner. With proven expertise in AI-powered industrial automation, IoT integration, and cloud-based solutions, Emorphis helps businesses design, build, and scale automation systems that deliver measurable results. From predictive maintenance to process optimization, our solutions drive innovation, safety, and long-term growth.

Connect with Emorphis today to discover how AI can redefine your industrial future and give your business the competitive edge it deserves.