Manufacturers often struggle with fragmented operations, disconnected teams, and outdated systems that slow productivity and impact customer satisfaction.

Salesforce for manufacturing companies offers an integrated solution to unify sales, operations, and service while unlocking valuable insights from data. It’s built to handle complex manufacturing needs with agility and intelligence.

- Streamlines sales processes with real-time visibility

- Improves service delivery and partner collaboration

- Enhances decision-making through AI-powered analytics

Let’s explore how Salesforce empowers manufacturing leaders to modernize operations and drive efficiency at every value chain stage.

Why Leverage Salesforce for Manufacturing Companies?

Manufacturing leaders face pressure to boost productivity, reduce delays, and adapt faster—but outdated tools and disconnected systems make that harder every day.

To stay competitive, manufacturers need more than quick fixes—they need a unified platform that brings together people, processes, and data. Salesforce helps break down silos across departments and empowers your teams with tools to make faster, more informed decisions.

- Gain full visibility across sales agreements, inventory, and partner networks

- Replace manual processes with real-time automation and smart workflows

- Empower service teams with connected field data and faster resolutions

- Strengthen partner relationships through transparent, shared dashboards

- Use predictive analytics to forecast demand and optimize production

- Centralize data for quick decisions across the supply chain and operations

Salesforce for manufacturing companies isn’t just a CRM, it’s a complete platform to unify your teams and fuel smarter growth.

Benefits of Using Salesforce for Manufacturing Companies

When manufacturers adopt Salesforce, they move beyond disconnected tools and manual processes. What they gain is clarity, speed, and the confidence to scale.

Salesforce isn’t just a platform it’s a growth enabler. It aligns sales, service, operations, and partner management, giving manufacturers the power to drive performance and respond to change with agility.

Here’s how that translates into real business benefits:

- Faster Sales Cycles: Streamlined workflows and quoting processes reduce delays and help teams close deals faster.

- Higher Forecast Accuracy: With real-time insights, manufacturers can plan production and inventory more precisely reducing overstock and missed demand.

- Improved Customer Satisfaction: Timely service, personalized engagement, and consistent communication build stronger, long-term customer relationships.

- Better Partner Relationships: Transparent, data-driven collaboration improves trust and efficiency with distributors and suppliers.

- Reduced Operational Costs: Automation eliminates manual tasks and errors, freeing up resources and reducing overhead.

- Stronger Strategic Decisions: Unified data and AI-powered analytics help leaders make smarter, faster decisions at every level.

In a competitive landscape, these aren’t just improvements they’re differentiators.

Want to implement Manufacturing Cloud? Explore our Salesforce Manufacturing Cloud Services and take the first step toward a smarter manufacturing operation.

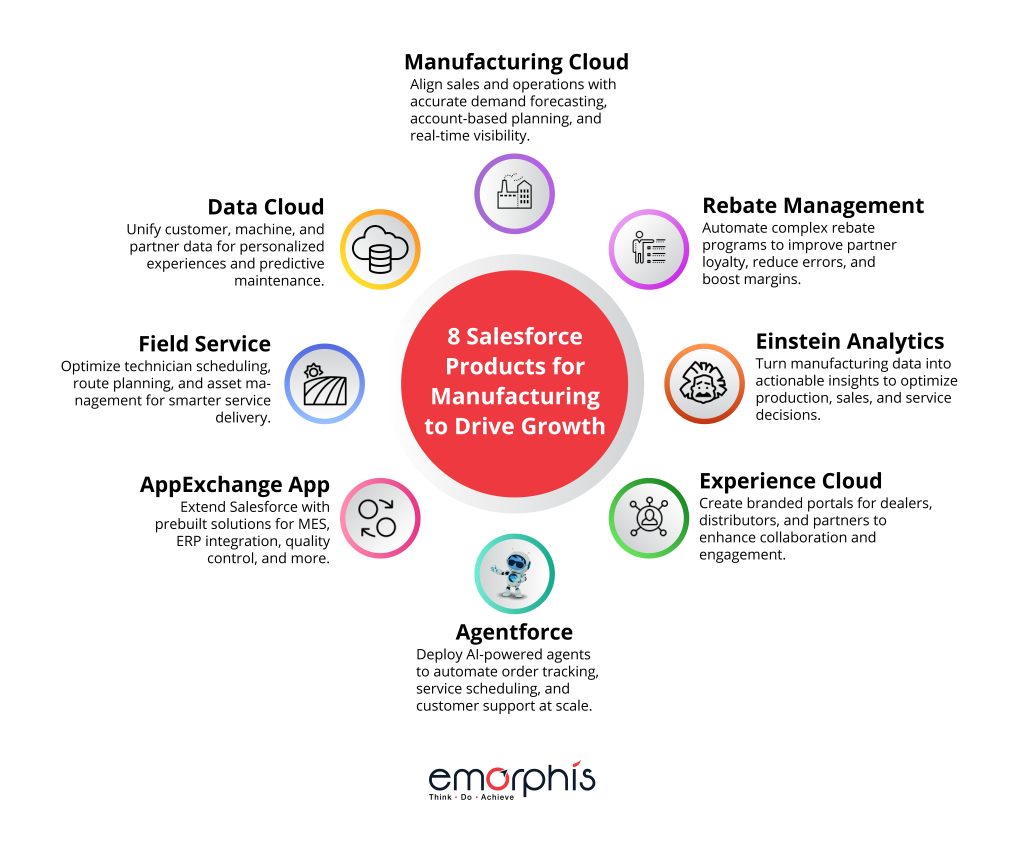

8 Essential Products of Salesforce for Manufacturing Companies

Manufacturing is no longer just about producing goods it’s about orchestrating complex operations across sales, service, supply chain, and partner ecosystems. And while legacy tools struggle to keep up, Salesforce offers a powerful, unified platform tailored to your industry needs. These eight essential Salesforce products are built to solve manufacturing-specific challenges, drive operational excellence, and accelerate growth.

1. Manufacturing Cloud

Disjointed sales and operations often lead to poor forecasts, missed opportunities, and costly inefficiencies. Manufacturing Cloud connects these teams with real-time visibility into customer agreements, order volumes, and production forecasts. It enables you to align operations with customer expectations, optimize inventory, and build a more predictable revenue stream.

• Manufacturing Cloud for Sales

Manufacturing Cloud for Sales empowers your sales teams with accurate pricing, real-time product availability, and streamlined approval workflows. You can manage long-term agreements with precision and reduce deal cycle times significantly.

• Manufacturing Cloud for Service

Customers expect fast, reliable service. Manufacturing cloud for services equips your service teams with full visibility into asset performance, warranty coverage, and maintenance schedules—so they can deliver timely support and build lasting trust.

2. Rebate Management

Managing complex rebate programs manually often leads to revenue leakage, errors, and strained partner relationships. Salesforce Rebate Management automates the entire lifecycle—from defining rebate criteria to calculating payouts. It gives your partners clarity and you, control.

3. Einstein/ CRM Analytics

You can’t make agile decisions with delayed reports. Einstein/ CRM Analytics helps you spot trends, track KPIs, and predict future outcomes using AI-driven insights. With intuitive dashboards and visualizations, your teams are empowered to act quickly and confidently.

4. Experience Cloud

A lack of transparency can damage dealer and distributor relationships. Experience Cloud for manufacturers let’s you build branded portals where partners can track orders, access key documents, and collaborate in real time—reducing support tickets and improving loyalty.

5. Agentforce

Field reps and service agents often struggle with inconsistent processes or missing information. Agentforce for manufacturers delivers AI-powered recommendations, dynamic guidance, and relevant knowledge at the point of service—helping them resolve issues faster and maintain consistency across channels.

6. AppExchange Apps

Every manufacturer has unique processes. AppExchange apps for manufacturing range from ERP and MES connectors to quality management and compliance tools, empowering manufacturers to streamline operations and ensure regulatory standards. You can easily extend Salesforce to fit your operations without building from scratch.

7. Field Service

Managing mobile teams and service schedules manually is inefficient. Field Service for manufacturers enables intelligent scheduling, mobile access, and real-time updates—helping you boost technician productivity and increase first-time fix rates.

8. Data Cloud

Data scattered across ERP, CRM, and service tools slows you down. The Data Cloud for manufacturers unifies data from multiple sources to build a complete customer and product view. You can trigger real-time alerts, deliver personalized experiences, and ensure everyone works with accurate, consistent data.

These products are more than just tools—they’re strategic enablers. They help you streamline operations, respond to market demands with agility, and turn data into action across every function of your manufacturing business.

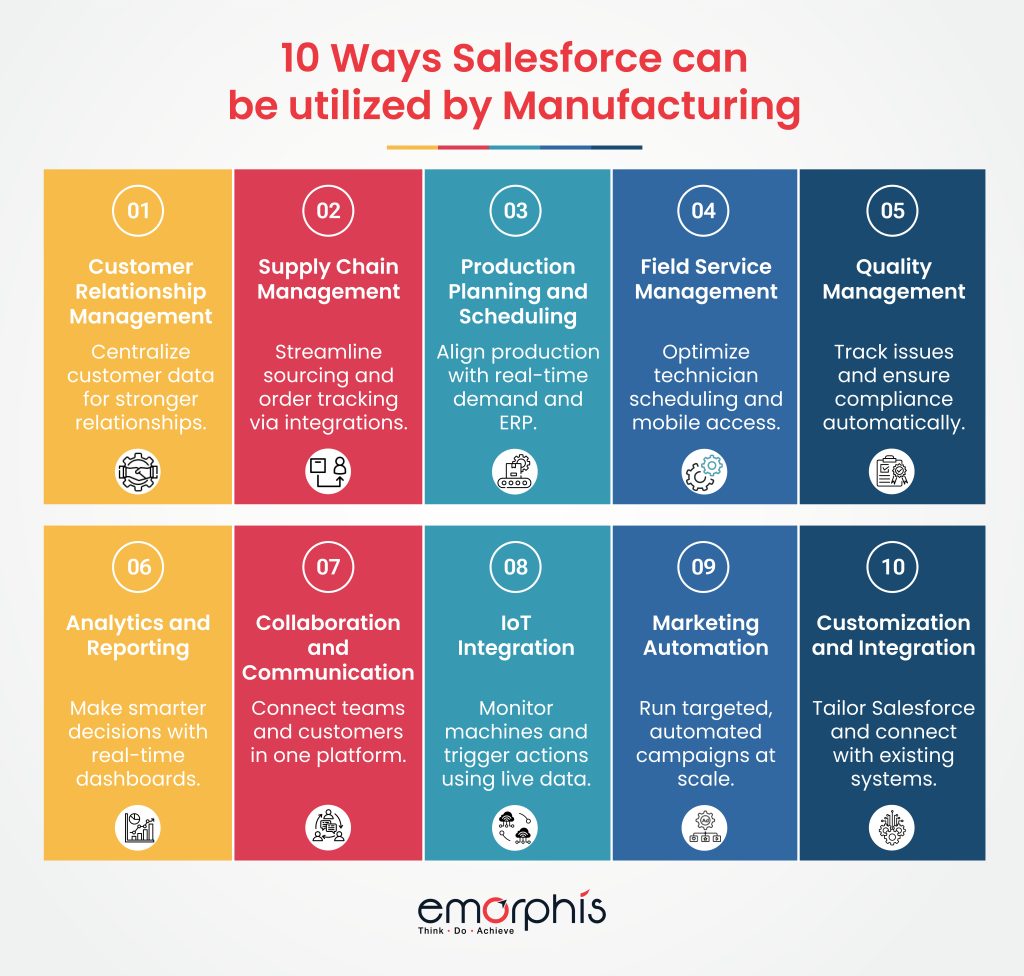

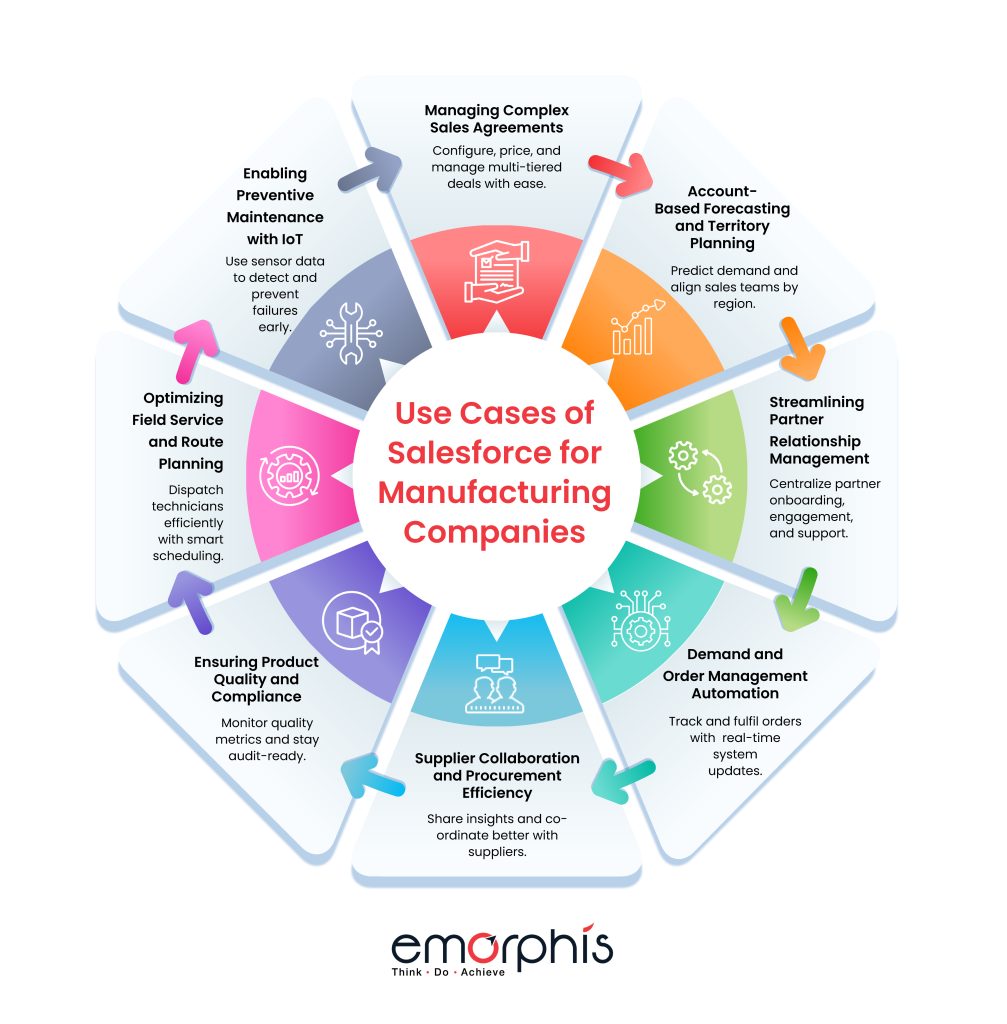

10 Ways Salesforce Can Be Utilized by Manufacturing Companies

Salesforce is far more than a CRM—it’s a complete platform that helps manufacturers run smarter, leaner, and more connected businesses. From streamlining customer interactions to managing production workflows and field service operations, Salesforce offers a wide range of tools that can be tailored to your needs.

Here’s how manufacturing companies can leverage Salesforce across different business areas:

1. Customer Relationship Management (CRM)

Strong customer relationships are at the heart of long-term success—and Salesforce gives manufacturers the tools to manage every touchpoint.

- Centralized Customer Data

Salesforce consolidates customer interactions, purchase history, agreements, and service cases in one place. This enables your sales, service, and support teams to access a 360-degree view of each customer—leading to more personalized and effective communication. - Sales Pipeline Management

You can track deals in progress, monitor key accounts, and forecast revenue with confidence. Salesforce helps your team focus on high-value opportunities and reduces delays in closing deals. - Customer Service

Respond to customer issues faster with case management, service level agreements, and knowledge bases. You can route cases automatically and offer self-service portals to improve the customer experience.

2. Supply Chain Management

Salesforce helps streamline supply chain operations with better collaboration and visibility.

- Vendor Management

Maintain detailed vendor records, track performance metrics, and manage supplier communications in a centralized platform. This allows procurement teams to make smarter sourcing decisions. - Inventory Management

While Salesforce doesn’t manage inventory directly, integrations with ERP and inventory systems allow for synchronized data—ensuring accurate stock levels and faster decision-making. - Order Management

Automate and track orders from quote to fulfilment. Salesforce CPQ (Configure, Price, Quote) streamlines order creation, while dashboards help teams monitor order status and delays in real time.

3. Production Planning and Scheduling

Efficient production starts with accurate planning—and Salesforce helps by aligning operations with real-time insights.

- Integration with ERP Systems

Connect Salesforce with ERP platforms to sync production schedules, materials availability, and job orders—so sales and operations stay aligned. - Demand Forecasting

Leverage historical data, customer trends, and market signals to predict future demand more accurately. Salesforce Einstein AI supports predictive modelling to prevent overproduction or stockouts.

4. Field Service Management

For manufacturers with onsite service needs, Salesforce ensures every visit is productive.

- Service Scheduling

Assign jobs to technicians based on location, skills, and availability using intelligent scheduling tools. Ensure that the right technician arrives with the right parts—on time. - Mobile Access

Give technicians access to job details, customer history, and manuals from their mobile devices. They can update job status, capture signatures, and log notes on the go.

5. Quality Management

Product quality and compliance are critical in manufacturing. Salesforce helps teams stay ahead of issues and meet industry standards.

- Issue Tracking

Capture, categorize, and resolve product issues quickly. Automated workflows help escalate critical quality problems and assign them to the right teams. - Compliance Management

Track regulatory documentation, audit trails, and corrective actions. Salesforce supports quality documentation, ISO compliance, and internal process standards.

6. Analytics and Reporting

Informed decisions are driven by data—and Salesforce puts actionable insights at your fingertips.

- Sales and Performance Analytics

Measure team performance, track quotas, and monitor revenue trends. Dashboards provide real-time visibility into key metrics that drive business outcomes. - Custom Dashboards

Tailor dashboards for executives, sales leaders, or plant managers—so each stakeholder has visibility into what matters most to them.

7. Collaboration and Communication

Siloed communication is a common challenge. Salesforce bridges those gaps internally and externally.

- Internal Collaboration

With tools like Chatter and Slack integration, your teams can collaborate on accounts, opportunities, or service issues—all within the Salesforce ecosystem. - Customer Portals

Give your customers and distributors secure access to order information, service cases, and key documents through Experience Cloud portals—improving transparency and reducing support load.

8. IoT Integration

Today’s smart factories depend on connected devices—and Salesforce supports real-time data from the shop floor.

- Connected Assets

Track performance of machinery and equipment through IoT sensors. This allows predictive maintenance and reduces downtime. - Data Collection

Stream device telemetry into Salesforce for analysis. Trigger alerts, service calls, or actions based on real-time conditions like temperature, vibration, or usage.

9. Marketing Automation

Manufacturers need to engage customers and partners with the right message at the right time—Salesforce makes that easier.

- Targeted Campaigns

Use segmentation, behaviour tracking, and campaign management tools to deliver personalized marketing efforts across email, social, and digital channels. - Lead Nurturing

Automate follow-ups, reminders, and educational content to guide prospects through the buying journey—ultimately converting more leads into customers.

10. Customization and Integration

Every manufacturer has unique needs—Salesforce adapts to fit your processes.

- Custom Apps

Build custom workflows and apps for specific functions like warranty management, safety inspections, or machine calibration tracking—all within the Salesforce platform. - API Integration

Connect Salesforce with your ERP, MES, financial systems, or third-party platforms to create a seamless flow of data across your organization.

With Salesforce, manufacturing companies aren’t just managing operations—they’re transforming them. Whether it’s sales alignment, partner collaboration, or production efficiency, the platform gives you the flexibility to adapt, innovate, and lead in today’s competitive market.

7 Challenges Solved by Salesforce for Manufacturers

Manufacturing companies often juggle complex operations, long sales cycles, and fragmented systems. These challenges can lead to inefficiencies, revenue loss, and customer dissatisfaction. Salesforce addresses these problems with tailored solutions that unify teams, improve visibility, and drive better outcomes.

- Disconnected Sales and Operations

Manufacturing Cloud bridges the gap with real-time visibility into agreements, forecasts, and production. - Inaccurate Demand Forecasting

Einstein Analytics delivers predictive insights to plan with greater accuracy and reduce overstock or shortages. - Complex Pricing and Quoting

Salesforce CPQ streamlines configurations, pricing rules, and approvals—speeding up deal closure. - Manual Rebate Management

Rebate Management automates tracking and payouts, improving accuracy and partner satisfaction. - Limited Customer and Partner Engagement

Experience Cloud enables self-service portals and transparent communication. - Lack of Real-Time Business Insights

Data Cloud unifies data, enabling faster, data-driven decisions. - Inefficient Field Service Operations

Field Service boosts technician productivity with optimized scheduling and mobile access.

Have specific challenges? Talk to our Manufacturing Cloud consultant today.

Examples or Use Cases of Salesforce for Manufacturing Companies

1: Managing Complex Sales Agreements

A manufacturer of industrial machinery needs to manage long-term contracts with complex pricing, discount schedules, and volume-based rebates over multiple periods.

Sales Agreements feature allows detailed structuring and real-time tracking of contract terms, aligning revenue recognition with production and delivery. It reduces errors, automates renewals, and ensures all stakeholders—sales, finance, and operations—stay updated with synchronized agreement data across systems.

2: Account-Based Forecasting and Territory Planning

A global manufacturer struggles to forecast revenue accurately at the account level and allocate resources efficiently across sales territories.

Salesforce enables territory-based segmentation and account-level forecasting to enhance strategic planning. Sales leaders can adjust forecasts based on real-time pipeline changes, identify high-potential regions, and distribute workload effectively, ensuring sales goals align with market potential and regional business trends.

3: Streamlining Partner Relationship Management

A company managing multiple distribution channels experiences delays and miscommunication due to a lack of centralized partner management tools.

Experience Cloud delivers a centralized, secure portal for real-time communication with distributors and resellers. Partners can track leads, register deals, view performance dashboards, and access updated documents—improving response times, increasing transparency, and fostering stronger, trust-based collaboration across the partner network.

4: Demand and Order Management Automation

A manufacturer faces frequent delays due to inaccurate order capture, disconnected systems, and inconsistent demand planning across departments.

Salesforce integrates CPQ, CRM, and ERP systems to create a streamlined quote-to-order process. It provides real-time demand visibility, automates approvals, ensures accurate pricing, and synchronizes order data—accelerating fulfilment and enabling cross-functional teams to collaborate more effectively.

5: Supplier Collaboration and Procurement Efficiency

A manufacturing enterprise relies on outdated communication with suppliers, resulting in misaligned delivery schedules and inefficient procurement processes.

Salesforce enables seamless data sharing and communication with suppliers through integrated portals and real-time updates. This helps align delivery schedules with production needs, minimizes delays, improves material availability, and enables procurement teams to make proactive decisions with up-to-date supplier performance metrics.

6: Ensuring Product Quality and Compliance

A manufacturer struggles with tracking product defects and maintaining compliance with evolving industry regulations.

Salesforce offers end-to-end quality management through issue logging, automated corrective action workflows, and compliance tracking dashboards. It ensures real-time collaboration between quality teams, engineering, and production—while maintaining detailed audit trails for industry certifications and improving long-term product reliability.

7: Optimizing Field Service and Route Planning

A field service team spends excessive time traveling due to manual scheduling and poor visibility into technician availability and route planning.

Salesforce Field Service uses AI-powered scheduling and route optimization to assign the right technician with the right tools for each job. Mobile access to customer history, service tasks, and maps reduces travel time, increases productivity, and improves first-time fix rates.

8: Enabling Preventive Maintenance with IoT

An equipment manufacturer wants to reduce downtime and maintenance costs by shifting from reactive to proactive service models.

By integrating IoT data and Einstein AI, Salesforce monitors asset performance in real time and triggers automated service workflows. Alerts are sent before failures occur, enabling timely maintenance, extending equipment life, and enhancing customer satisfaction with fewer unexpected breakdowns.

Case Study: Streamlining Sales and Order Management for Manufacturing Company

At Emorphis Technologies, we recently partnered with a global manufacturing company facing operational inefficiencies due to disconnected systems. Despite using Salesforce CRM, Oracle CPQ, and Oracle ERP, the lack of integration across platforms resulted in data silos, redundant manual work, and inconsistent customer experiences—ultimately impacting sales performance and operational agility.

Solution Overview

To address these challenges, our Salesforce integration consultants implemented a custom solution that seamlessly connected Oracle ERP, Oracle CPQ, and Salesforce CRM into a unified platform.

Key elements included real-time data synchronization, automated order processing, and integrated sales pipeline visibility. This integration enabled the client to simplify their complex product configurations, streamline quoting, and improve coordination between sales and operations.

Key Outcomes

- Increased sales efficiency through reduced manual work and process automation

- Enhanced customer satisfaction with accurate pricing and faster order fulfilment

- Improved visibility and decision-making with real-time data across sales and inventory

Interested in learning more about how we achieved these results? Check out the full story here.

Transform how you sell, forecast, and collaborate. Talk to a Salesforce Manufacturing Cloud consultant today

Frequently Asked Questions (FAQs)

How is Salesforce used in manufacturing?

Salesforce is used in manufacturing to streamline sales processes, improve demand forecasting, manage partner relationships, and enhance customer service. It provides a unified platform that connects sales, operations, and service teams—offering real-time visibility into agreements, inventory, and orders. Manufacturers also use Salesforce to automate quoting, manage field service, and leverage data for smarter decision-making.

How do I get started with Salesforce for manufacturing?

To get started with Salesforce for manufacturing, begin by identifying your key pain points—such as disconnected systems, manual order processing, or forecasting challenges. The next step is to consult with a Salesforce Manufacturing Cloud expert who can assess your business needs and recommend a tailored implementation strategy, including integrations and required customizations.

What is the key first step for Manufacturing Cloud implementation?

The key first step is aligning your sales and operations teams around common goals and data. Start by auditing your existing sales agreements, forecast models, and processes. Then, work with a Salesforce consultant to define business rules, data mapping, and integration requirements that will guide a smooth Manufacturing Cloud deployment.

Can we integrate Salesforce Manufacturing Cloud with other ERPs?

Yes, Salesforce Manufacturing Cloud can be integrated with ERP systems like Oracle, SAP, and NetSuite. Integration allows for real-time data synchronization between your CRM and ERP, ensuring consistent order details, inventory levels, pricing, and financial data. APIs and middleware tools help create seamless workflows between systems.

Is Salesforce useful for discrete and process manufacturers alike?

Absolutely. Salesforce is highly customizable and supports both discrete and process manufacturing models. Discrete manufacturers benefit from product configuration, quoting, and partner management tools, while process manufacturers use Salesforce for batch tracking, compliance workflows, and real-time customer engagement.

What types of manufacturing companies benefit most from Salesforce?

Salesforce is especially valuable for mid-sized to large manufacturing companies with complex sales processes, multiple channel partners, and a need for better operational visibility. Companies in automotive, industrial equipment, high-tech, medical devices, and consumer goods manufacturing see significant ROI with Salesforce adoption.

Can I manage partners and distributors through Salesforce?

Yes, Salesforce Experience Cloud allows you to build custom partner portals where distributors and channel partners can view orders, track inventory, access sales materials, and collaborate in real time. This improves transparency, reduces back-and-forth communication, and strengthens channel relationships.

Conclusion

Digital transformation in manufacturing isn’t optional—it’s essential. Salesforce empowers manufacturers to unify systems, automate operations, and drive smarter decisions across sales, service, and production workflows.

With the right tools and strategy, manufacturers can reduce inefficiencies, improve forecasting, and deliver exceptional customer and partner experiences.

Salesforce for manufacturing companies creates a foundation for scalable growth and operational excellence.

Ready to modernize your manufacturing operations?

Contact us today for a free consultation!

Also, explore 7 Reasons to Drive Business Results with a Manufacturing Salesforce CRM